EQUAL SAFETY

In addition to getting people out on the road there's one thing we take very seriously - Safety.

Our philosophy is that everyone should be able to travel safely in a vehicle regardless of adaptation needs. As a global leader it is our responsibility to continuously strive for a higher level of safety within the vehicle adaptation industry.

One way of achieving this is to offer high quality products that are both safe and functional. To guarantee our end users’ safety, BraunAbility products are designed and tested according to relevant directives and standards. We also work together with users, organisations, the automotive industry and other interested parties to constantly push for increasingly stringent safety requirements.

Learn more about safety

BraunAbility Safety Centre

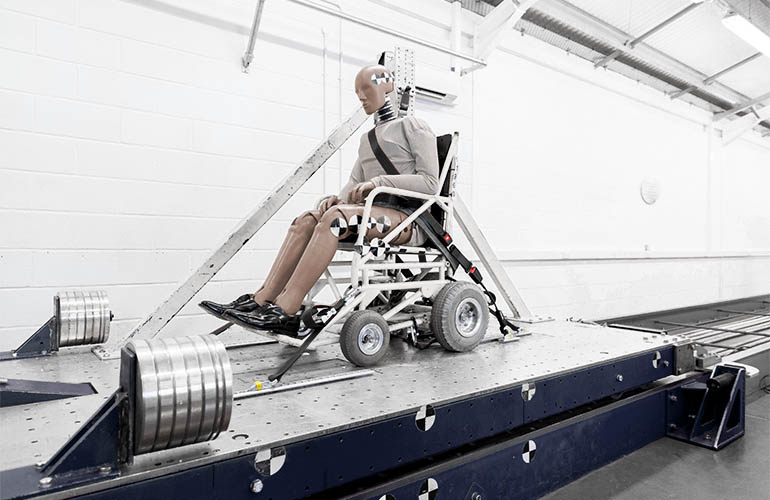

To remain in the front line among producers of safe and reliable vehicle adaptation products we have invested in multiple inhouse test facilities. Here our products must pass various tests before being released onto the market. Static pull tests, climate tests and cycle tests are examples of tests that we perform at our Safety Centre. Dynamic crash tests are performed by by Q'Straint at the iQ Center in the UK. For the tests we don’t perform in-house we team up with RISE – Research Institutes of Sweden, VCA in the UK and TÜV in Germany.

Standards and paperwork

The rules and regulations regarding vehicle adaptation differ widely all over the world. To make sure our end users get the independence they desire we will provide all the necessary certificates and documents often required by road authorities and car inspection agencies.

Quality Control

Everything we do is carefully tested and documented. To provide peace of mind for everyone, design, development, production and installation plus our final checks are certified under the quality system ISO 9001. We want to be able to offer our end users a vehicle with the same safety conditions it had before being adapted.

Lean Production

All throughout the company we have adopted the philosophy of Lean Production. A monumental and long-term investment that affects all parts of the company and everyone working in it. Lean helps us refine how a worktable is organised as well as it helps us recognize and develop the individual skills of an employee.

All throughout the company we have adopted the philosophy of Lean Production. A monumental and long-term investment that affects all parts of the company and everyone working in it. Lean helps us refine how a worktable is organised as well as it helps us recognize and develop the individual skills of an employee.

A simplified explanation is that it helps us reduce waste in all forms. Waste such as overproduction, wait, stock, movement, rework, overwork, transport and untapped creativity of the workforce.

Strive for perfection – know that you are not

The notion that nothing is perfect has a central role in Lean Production. There is always room for improvement. This is usually referred to as continuous improvement and it’s an area where the entire workforce is encouraged to constantly look for possible improvements. Suggested changes are then audited, then evaluated before being adopted or dropped. The goal is to become a constantly evolving and learning organisation. In conclusion, Lean helps us build a trustworthy, solid foundation for our employees, customers and owners.